INNOVATION

BETWEEN THE SHEET METAL

METAL CARPENTRY INDUSTRY IN IRON - STEEL - ALUMINUM - ALLOYS

PALUAN metal carpentry

Industry 4.0

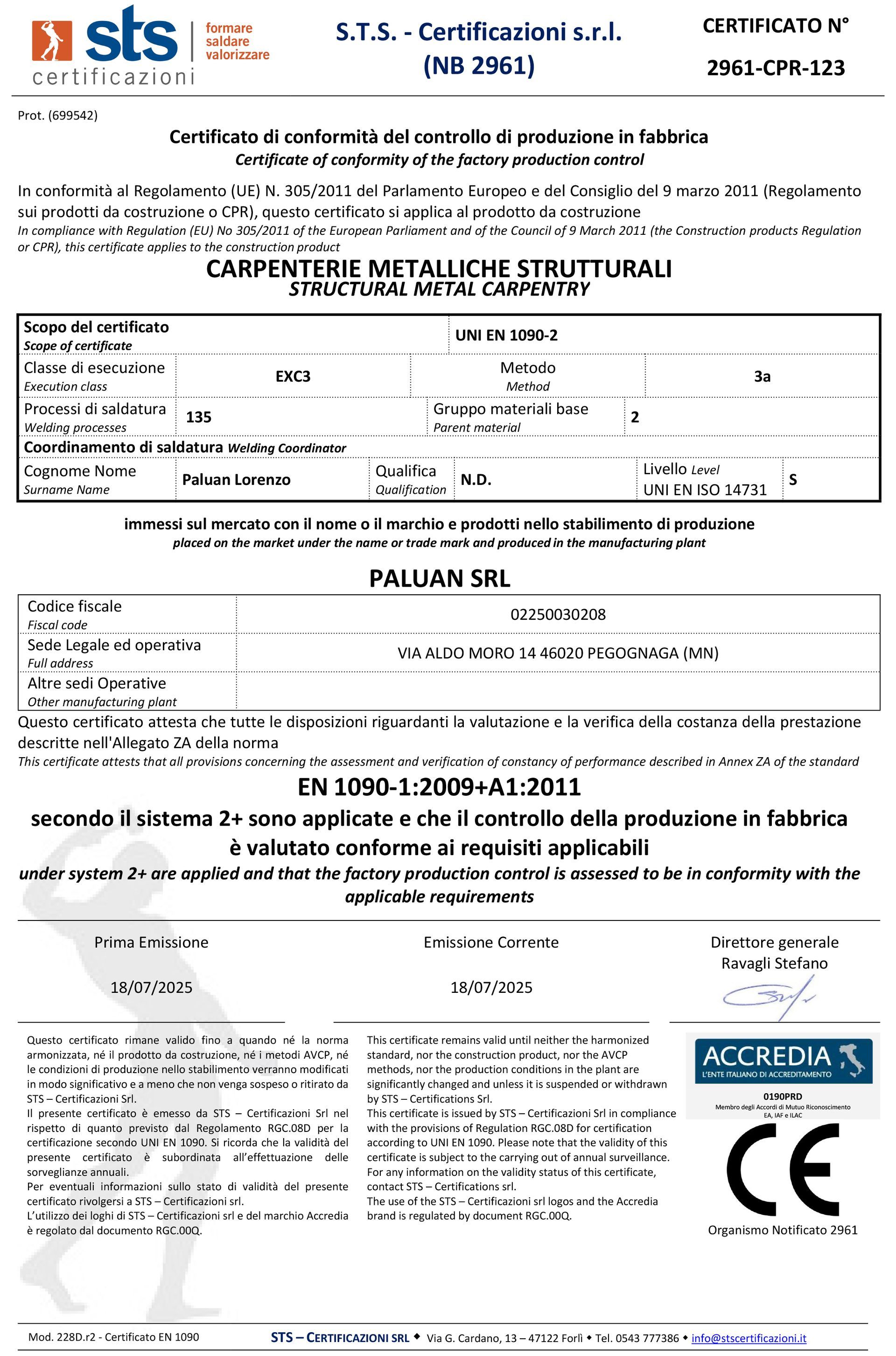

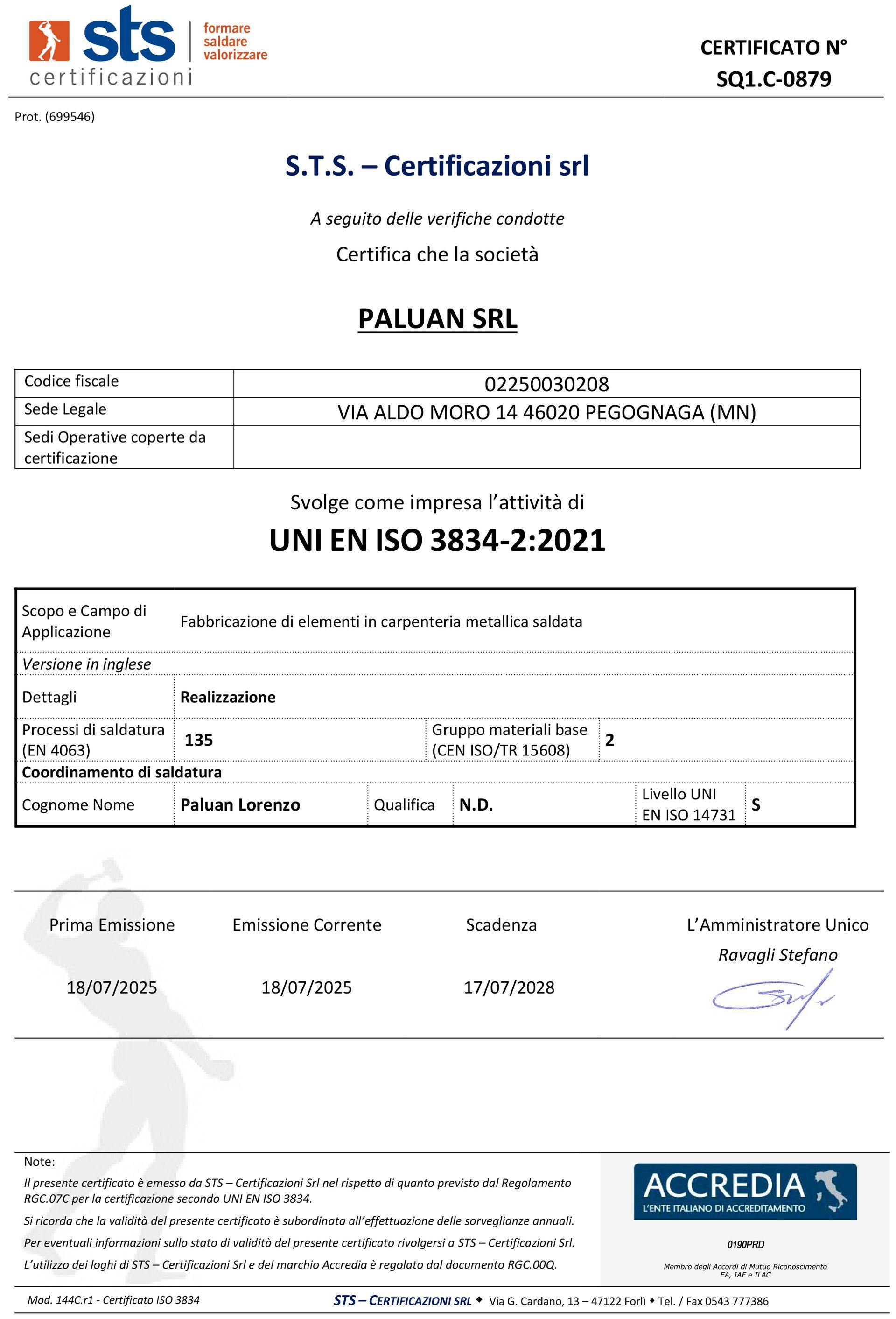

Paluan Srl, an Industry 4.0 company, has been producing metalwork in iron, steel, aluminum, and other alloys for over 44 years, using quality materials that are meticulously inspected.

Paluan operates in 3 owned factories in the same area with a production organization consisting of 4 departments:

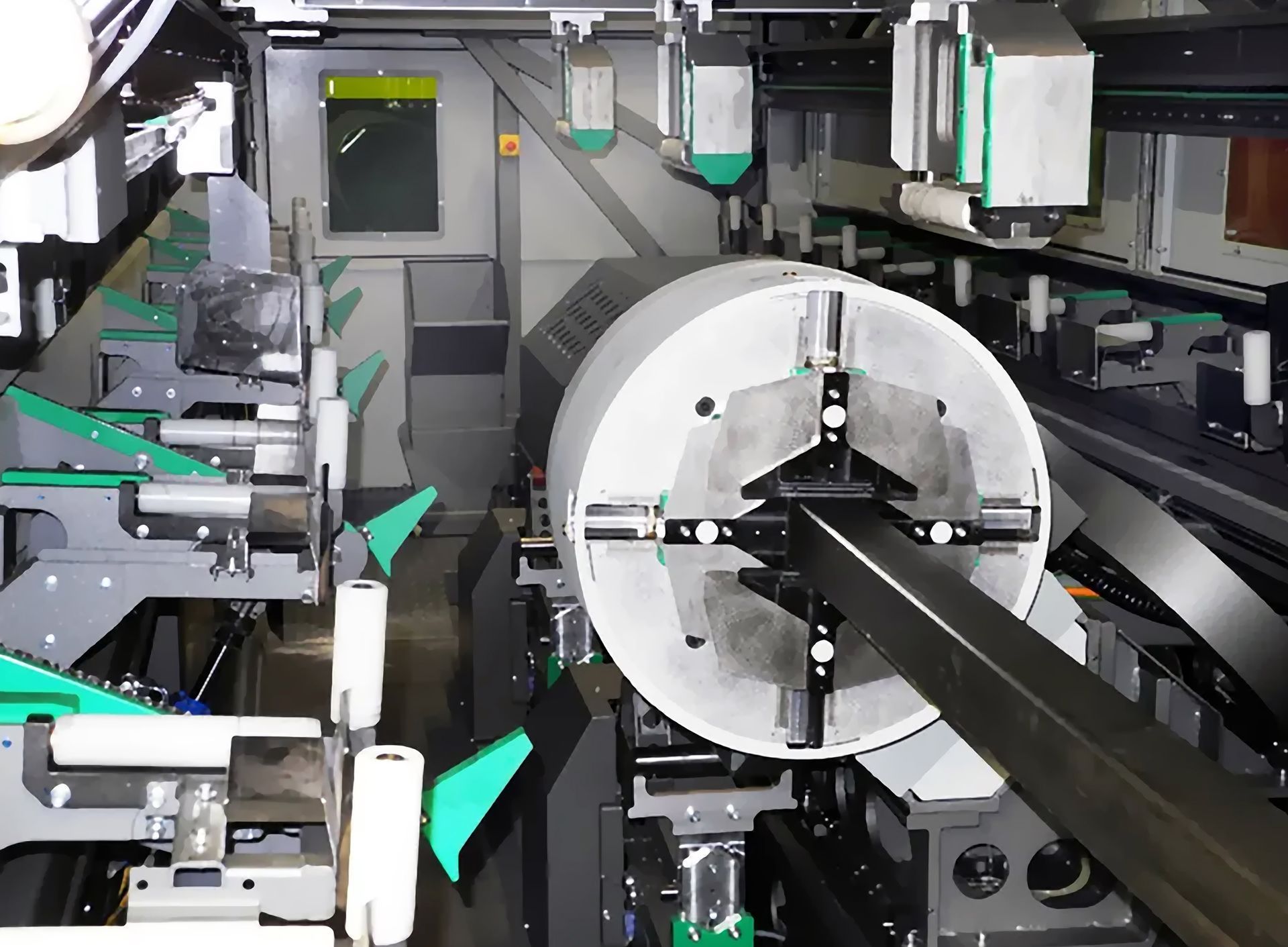

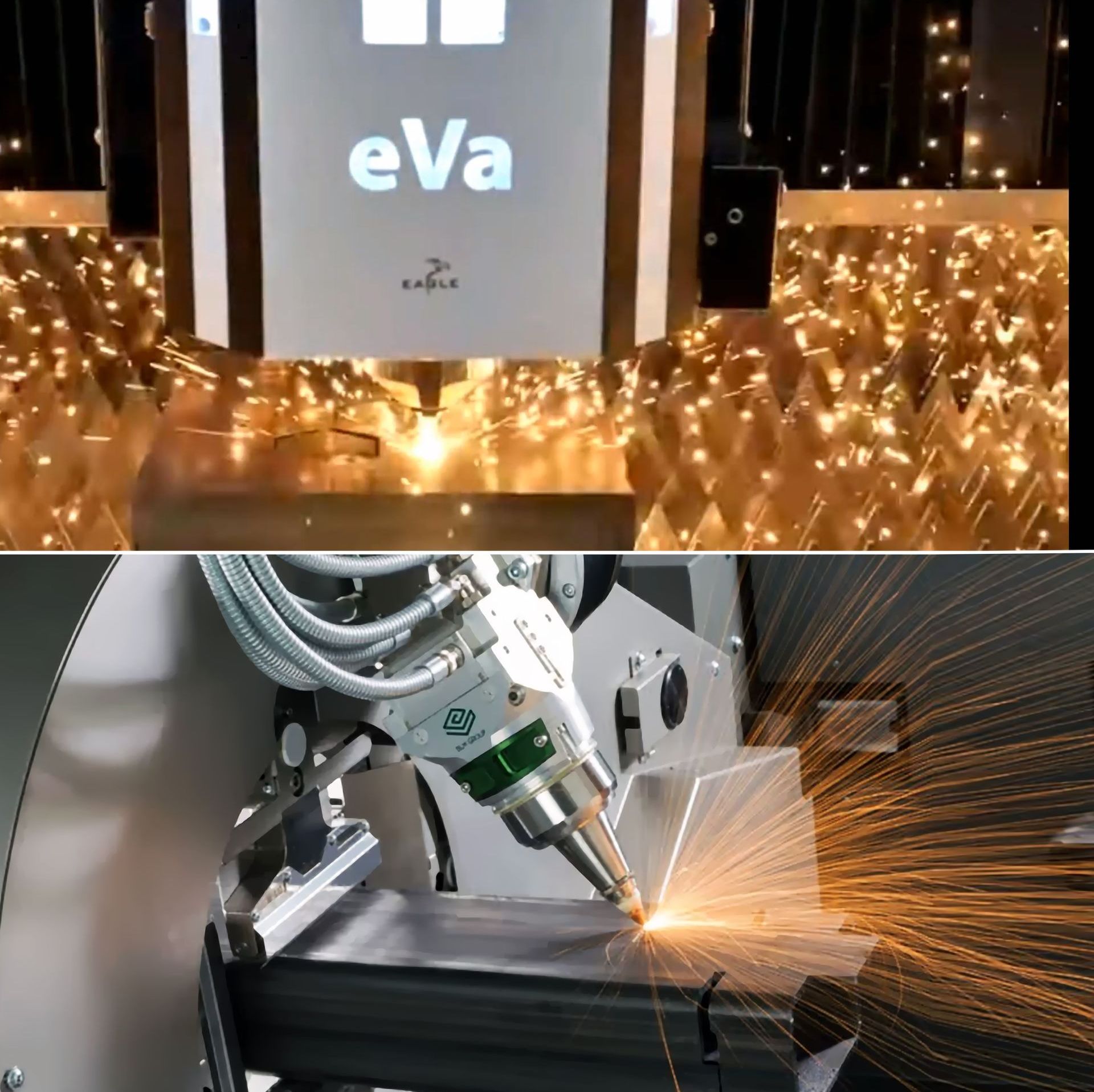

Laser Cast

Laser Tube Distribution

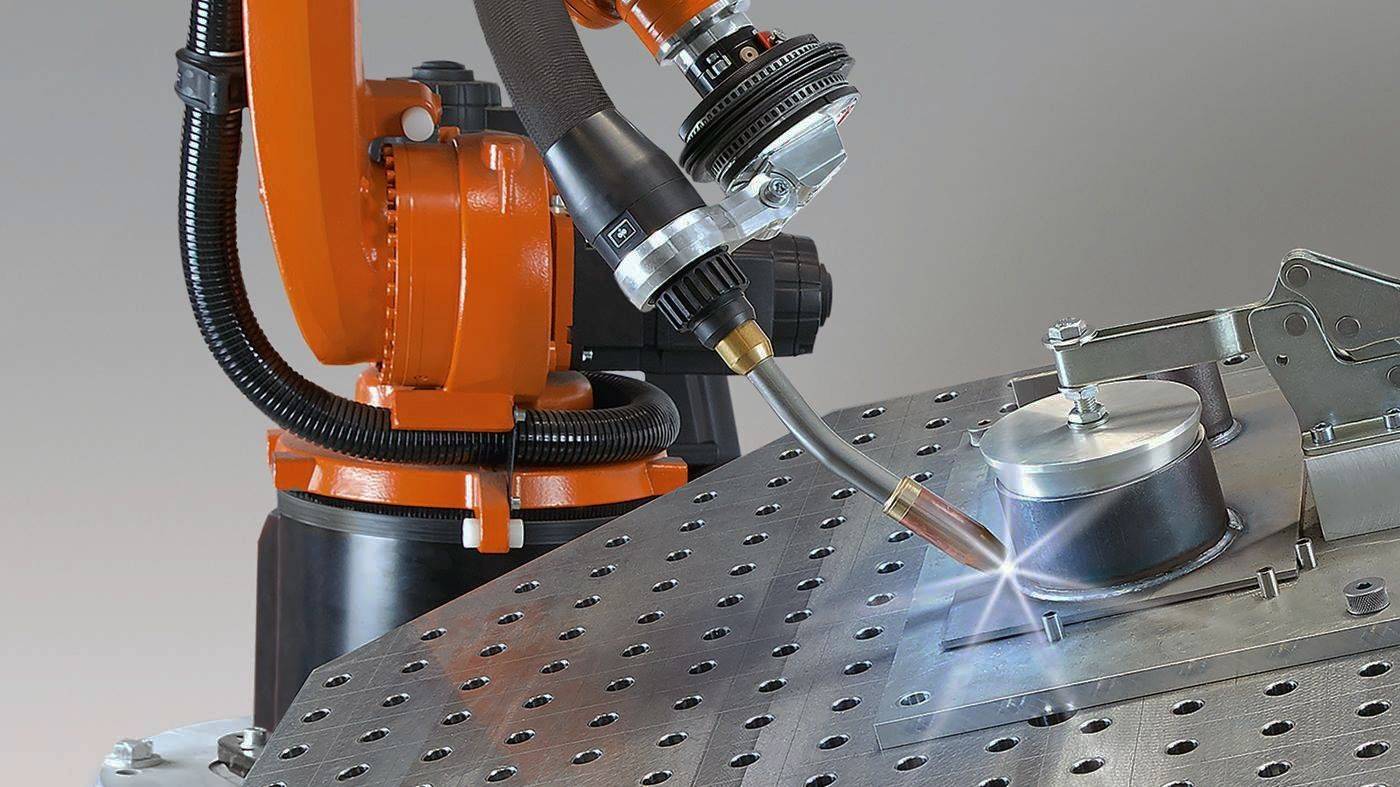

Welding Department

Turning Department - Work Centers Tube Bending Department - Stamping and Shearing

At Paluan, 50 people work on the machines, including employees and technicians. The company also relies on external collaborators, especially for material finishing.

TYPE OF PRODUCTION

Paluan produces light and heavy metal carpentry to design in small, medium and large series, and in particular:

Custom pieces of any size.

Large pieces requiring special transport.

Creation of prototypes based on drawings for the creation of new models.

Creation of prototypes for the study of subsequent industrialization.

Production of large structures for large applications.

Paluan operates in Pegognaga (Mantua) and over the years has consolidated a customer base of all sizes throughout northern Italy.

INDUSTRY 4.0

Paluan is an Industry 4.0 facility equipped with integrated industrial automation, supported by a computer network that links all processes. In addition to greater precision and speed, Industry 4.0 technology allows for constant monitoring of the production process, improving product quality and scheduling accuracy, resulting in greater production efficiency and a significant reduction in waste.

The company is specialized and equipped to produce custom-designed parts in small, medium, and large series with a high level of automation, excellent quality, and high productivity, supported by significant technological investments that make Paluan one of the most important companies in the sector.

Paluan also handles prototyping upon customer request. To carry out this activity, it has set up a department where a group of technicians assemble even large prototypes.

In addition to building prototypes, Paluan, with its technical office, carries out studies for subsequent industrialization, providing the customer with a complete service.

The just-in-time production method allows for third-party processing, satisfying a wide range of requests through the immediate availability of materials and machinery.

The Kan Ban method satisfies the customer who needs to plan their production lines with safety and precision.

Paluan then plans staggered deliveries based on the customer's initial order according to his call.

PALUAN is still growing

Since January 2025, Paluan Srl has continued to grow. The acquisition of NUOVA ARTIGIANFER SRL, a long-standing company specializing in tube bending and metalwork, has allowed us to expand our offerings and better meet our customers' needs. A synergy of experience and innovation for increasingly advanced solutions.